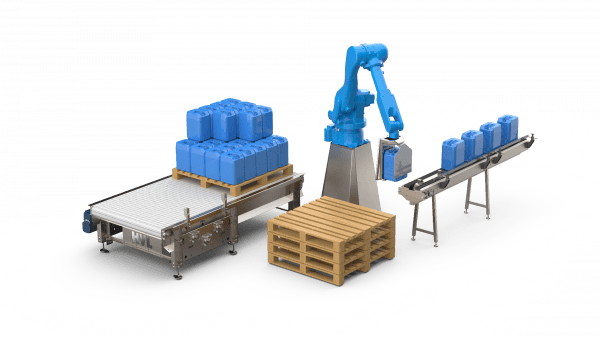

TFS Filling Solutions shows Finch and IBC Tilter in action

TFS Filling Solutions is showcasing the versatile Finch Filling Line and robust IBC tipper, which together provide an efficient and safe total solution for filling and packaging processes.

Whether stacking jerry cans, buckets, boxes or bag-in-boxes, TFS’ palletizer stacks them in a desired pattern. Due to its versatile capabilities and the use of tool changers, the palletizer can be quickly converted to process a different product. This makes it suitable for a variety of sectors, such as the food industry, chemicals, beverage industry, logistics, etc.

Supply voltage

3 fase 400V ~ 50 Hz + N, PE

Compressed Air

6 bar

Load by weight

5 kg to 180 kg

Robot equipment

Yaskawa

One of the main advantages of the palletizer is ability to create various stacking patterns. Thanks to advanced software, the robot can apply different configurations such as tightly stacked layers, cross stacking or even specific patterns depending on product type and customer requirements. This ensures maximum utilization of available pallet space, which can lead to lower transportation costs and more efficient use of storage space.

The TFS palletizer can stack jerry cans, buckets, boxes and bag-in-boxes in various sectors, thanks to quick changeover with tool changes.

With advanced software, the palletizer can create various stacking patterns, leading to more efficient use of storage space and lower transportation costs.

The tool change system allows lightning-fast adjustment so that the robot can process different products with grippers or suction cups.

The use of the palletizer reduces physical strain for employees, lowers absenteeism and increases overall workplace efficiency.

The palletizing robot is equipped with an advanced tool changing system. This allows rapid tool changes to process different products. For example, it is possible to equip the robot with grippers for boxes or cans or suction cups for fragile products. This flexibility makes the robot multifunctional and suitable for companies working with various product types.

The use of a palletizer eliminates the manual stacking of heavy boxes and cans. This will significantly reduce the physical strain on employees. This not only results in a lower risk of injury and absenteeism but also increases overall efficiency on the shop floor. The robot can continue working without a break and ensures a consistently high stacking rate. Beneficial for efficiency and high productivity.

View the available downloads and technical data sheets of the Palletiser here. Discover all specifications and possibilities (such as ATEX version) for your production process.

Do you have a specific challenge regarding filling solutions or automation? We’d be happy to brainstorm with you. Schedule a non-binding consultation and discover how TFS can offer tailored innovations for your production.

Joep (Account Manager TFS)

Joep (Account Manager TFS)

Discover more about our solutions! Download the brochure and get a complete overview of our innovative products and services. Be inspired by what TFS Filling Solutions can do for your business.

For every machine, we have a clear datasheet available. Download the datasheet and discover all technical specifications and possibilities.