TFS Filling Solutions shows Finch and IBC Tilter in action

TFS Filling Solutions is showcasing the versatile Finch Filling Line and robust IBC tipper, which together provide an efficient and safe total solution for filling and packaging processes.

Even though an operator is required for operation, the turnaround time becomes significantly faster thanks to the automated filling function. The operator can therefore fill more units in a shorter time compared to manual filling, increasing productivity. The machine automatically stops once the set quantity is filled, ensuring accurate dispensing and guaranteeing the speed of the process. In addition, waste is minimized. The result is high consistency and quality of the final product.

Supply Voltage

230V ~ 50 Hz + N, PE

Compressed Air

6 bar

Capacity

Dependent on product/weight

Pneumatics

Festo

Weighting

Penko

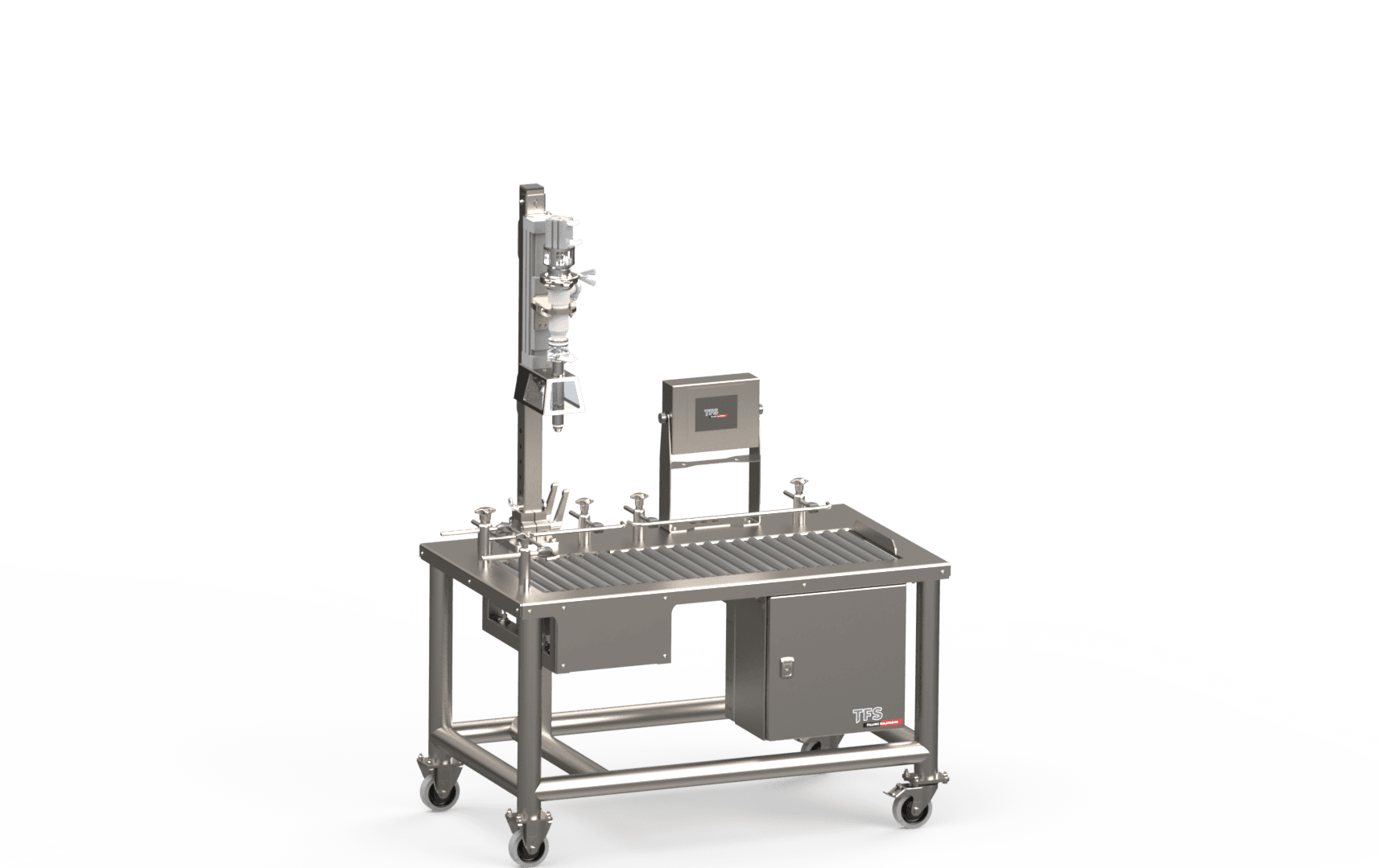

The Finch Filling Line is easy for an operator to operate and simple to adjust for height and weight. This makes it possible to handle a variety of packaging types and sizes. Think of all kinds of bottles, jerry cans and bag-in-box systems. This makes the Finch Filling Line versatile in different industries. The thoughtful and simple design requires little maintenance and allows for easy cleaning. This reduces downtime and ensures long machine life without high maintenance costs.

The Finch Filling Line is a semi-automatic filling machine that increases efficiency in various industries such as food, chemical and cosmetics, with an attractive investment option.

With a user-friendly control panel, the Finch Filling Line can be easily set up for different containers and sizes, from bottles to jerry cans.

The automated filling function allows the operator to fill more units faster, resulting in higher productivity and minimizing waste.

The Finch Filling Line can be expanded with options such as a roller conveyor and automatic cap sealer for increased capacity and ease of use.

The semi-automatic Finch Filling Line filling machine works pneumatically and has a fast and accurate weighing capacity. The filling machine is very easy to operate:

The Finch Filling Line can be expanded with various options as desired. For example, a roller conveyor is available as a weighing platform combined with a feed/discharge conveyor. This not only allows a higher capacity to be realized, but also reduces the burden on the operator. A lifting aid is also among the options so that the load when lifting the packages is reduced.

We also offer an automatic cap sealer for even more convenience and efficiency plus a fully electric version. Get extensive information and inspiration from our specialists. TFS will gladly think with you about the filling solution that best suits your situation.

The machine is also available in an ATEX version, specially developed for explosive environments, guaranteeing maximum safety and compliance with directives.

View the available downloads and technical data sheets of the Finch Filling Line here. Discover all specifications and possibilities for your production process.

Do you have a specific challenge regarding filling solutions or automation? We’d be happy to brainstorm with you. Schedule a non-binding consultation and discover how TFS can offer tailored innovations for your production.

Joep (Account Manager TFS)

Joep (Account Manager TFS)

Discover more about our solutions! Download the brochure and get a complete overview of our innovative products and services. Be inspired by what TFS Filling Solutions can do for your business.

For every machine, we have a clear datasheet available. Download the datasheet and discover all technical specifications and possibilities.